A Brushless DC Motor (BLDC Motor) is a type of electric motor that operates without the use of brushes, which are mechanical components found in traditional brushed motors. Instead of using brushes to transfer electrical current to the motor's rotating part (rotor), a BLDC motor uses electronic commutation through a controller.

A Brushless DC (BLDC) Motor is designed with several essential components that work together to produce smooth and efficient motion. Below are the key components of a BLDC motor:

The stator is the stationary part of the motor.

It contains coils or windings that generate a rotating magnetic field when energized.

Typically made from laminated steel sheets to reduce energy losses.

The windings are often arranged in a three-phase configuration.

The rotor is the rotating part of the motor.

It consists of one or more permanent magnets attached to or embedded within a core.

The rotor aligns with the rotating magnetic field produced by the stator, causing it to spin.

These sensors detect the rotor's position.

They send signals to the controller to determine which stator winding to energize next.

Some BLDC motors are sensorless and rely on back-EMF (electromotive force) to detect rotor position instead.

The controller or ESC manages the commutation process electronically.

It receives input from the Hall sensors and sends the appropriate current to the stator windings.

It controls speed, direction, and torque of the motor.

The shaft is the central rotating element connected to the rotor.

It delivers mechanical power to whatever device or system the motor is driving.

Often supported by bearings for smooth, low-friction rotation.

Bearings allow the rotor and shaft to spin smoothly within the stator.

High-quality bearings reduce friction, noise, and wear, improving motor lifespan.

The housing encases all internal components.

Provides mechanical protection and may also help with heat dissipation.

These components work together to create a highly efficient, durable, and reliable motor suitable for a wide range of applications—from consumer electronics to electric vehicles and industrial machinery.

Brushless dc motors come in several different types, categorized based on rotor position, construction, and commutation method. Each type is designed for specific performance needs and application scenarios.

In this type, the rotor is located inside the stator windings.

This is the most common design.

It provides better heat dissipation since the stator (where heat is generated) is mounted on the outer casing.

Offers high torque and high-speed capabilities.

Applications: Power tools, industrial machinery, home appliances, automotive systems.

Here, the rotor surrounds the stator windings.

The rotor rotates around a fixed stator, making it larger in diameter, which increases torque at lower speeds.

Tends to have better inertia stability and quieter operation.

Applications: Cooling fans, drones, electric bicycles, and compact appliances.

Equipped with Hall Effect sensors or optical encoders to detect the position of the rotor.

The controller uses this data to commutate accurately.

Provides precise speed and position control, especially useful in variable load conditions.

Applications: Robotics, CNC machines, medical equipment, industrial automation.

Does not use physical sensors to detect rotor position.

Instead, it relies on Back Electromotive Force (Back-EMF) to determine when to switch current in the stator windings.

More cost-effective and durable, but not suitable for low-speed or high-precision applications.

Applications: Drones, electric tools, pumps, fans.

Uses trapezoidal-shaped back-EMF waveform.

Simpler and more economical in design and control circuitry.

Produces more torque ripple compared to sinusoidal motors.

Applications: Small appliances, cost-sensitive industrial systems.

Generates a sinusoidal back-EMF, resulting in smooth torque output.

Requires a more complex controller, often involving Field Oriented Control (FOC).

Offers better efficiency, lower noise, and superior performance.

Applications: High-end servo systems, electric vehicles, aerospace systems.

Has no iron core in the rotor, making it extremely lightweight and fast-responding.

Delivers very low inertia and minimal electromagnetic interference.

Usually smaller in size, but more expensive to manufacture.

Applications: Precision instruments, medical tools, miniature drones, high-speed cameras.

There are various types of Brushless dc motors tailored for specific needs:

Inner Rotor for power and efficiency.

Outer Rotor for high torque and quiet operation.

Sensor-Based for accuracy.

Sensorless for simplicity and cost savings.

Trapezoidal and Sinusoidal for waveform control.

Coreless for ultra-light and precision tasks.

Choosing the right type depends on your application requirements, including size, speed, torque, cost, and control complexity.

BLDC Motors can be categorized into different types based on rotor placement, control mechanism, and sensing technology.

|  |  | ||

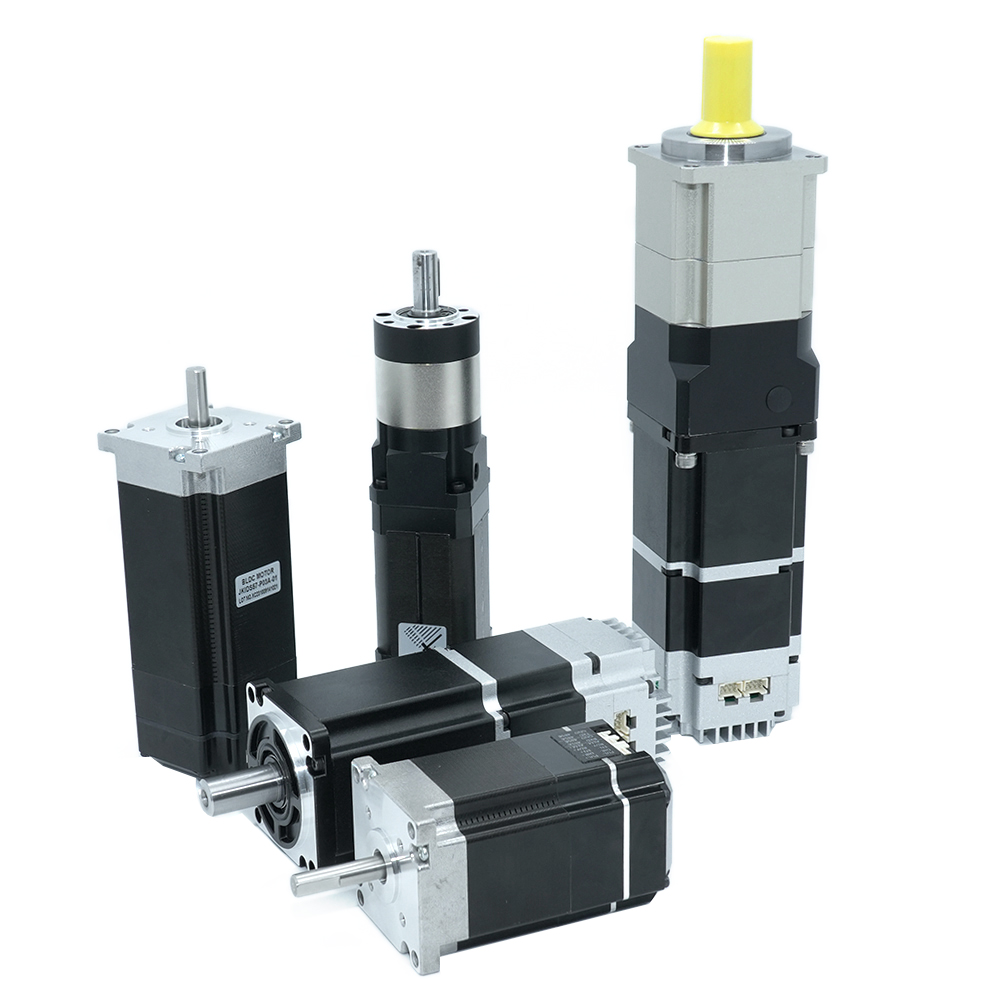

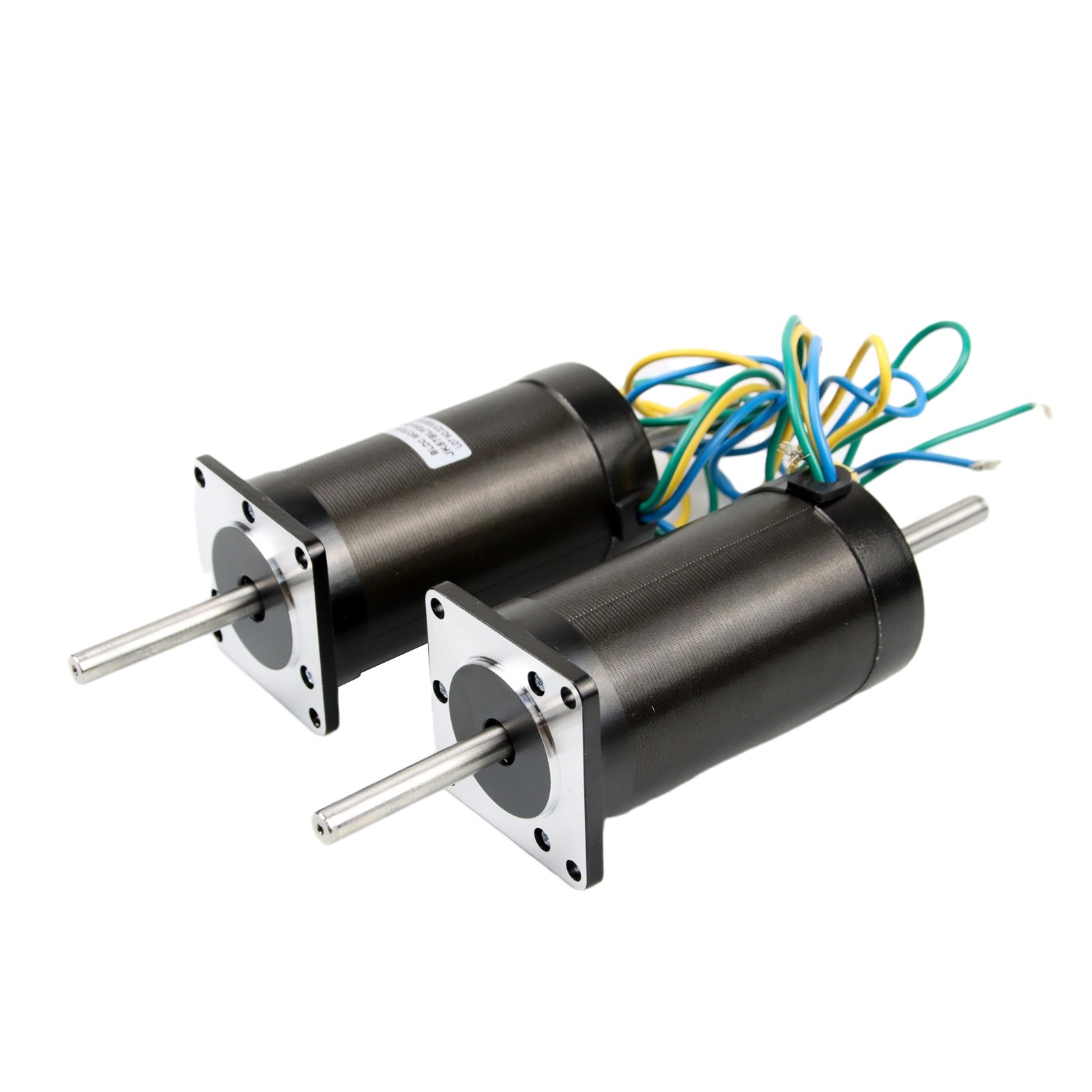

| Standard Bldc Motors | Geared Bldc Motors | Integrated Bldc Motors | Brake Bldc Motors | Bldc Motor with Encoder |

| 33mm /42mm /57mm /60mm /80mm /86mm /110mm /130mm | Planetary Gearbox / Spur Gearbox / Worm Gearbox | Pulse / RS485 / Canopen | 33mm /42mm /57mm /60mm /80mm /86mm /110mm /130mm | Incremental Encoder / Absolute Encoder / Optical Encoder / Magnetic Encoder |

|  |  |  | |

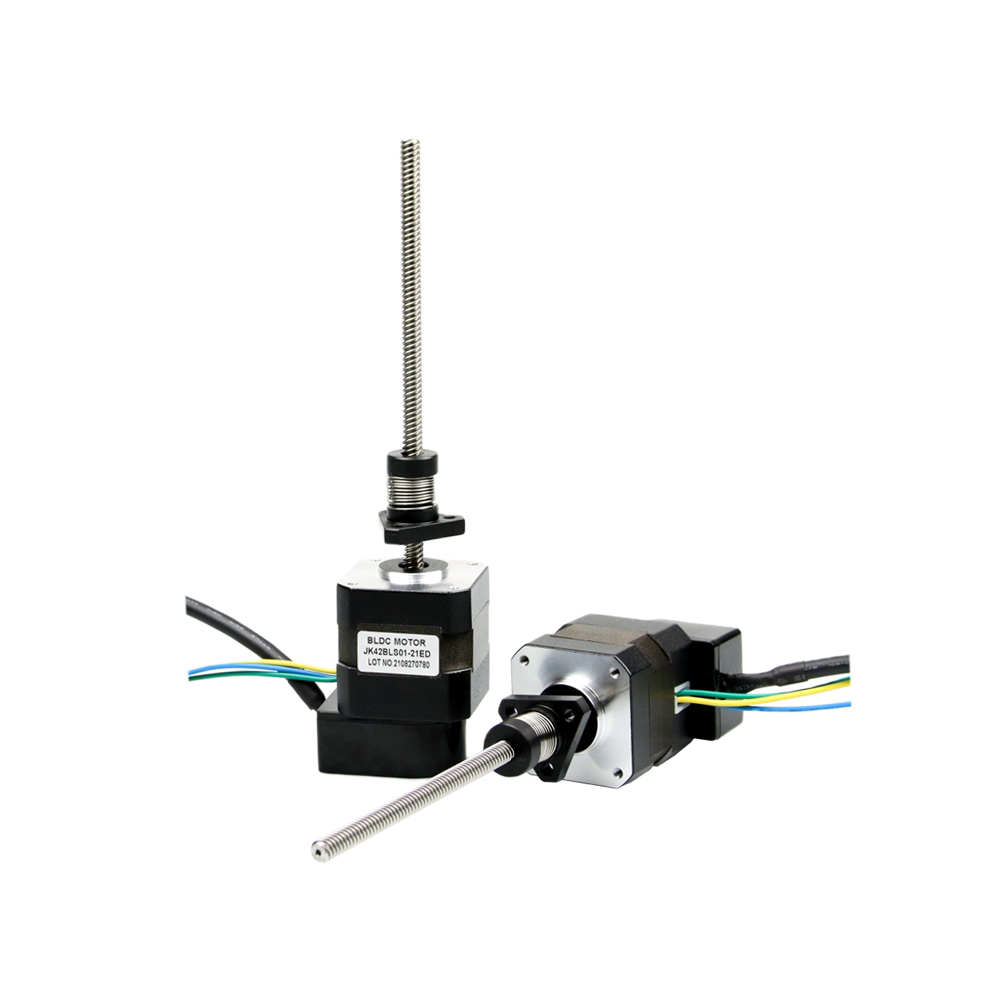

| Linear Bldc Motors | IP65 Waterproof Bldc Motors | Out Runner Bldc Motors | Coreless Dc Motors | Dual Shaft Bldc Motors |

| External T-type / Ball Screw / Non-captive lead screw | IP30 / IP54 / IP65 / IP67 Waterproof and dustyproof | 24V / 30-70W Power | Gearbox / encoder / Lead Screw... | Customized |

if you need customized Bldc Motors, please contact us.

A Brushless DC Motor (BLDC Motor) operates using electronic commutation instead of mechanical brushes. It combines permanent magnets on the rotor and electromagnets on the stator to generate rotation through precise electronic control.

When the motor is turned on, electrical power is supplied to the stator windings (the stationary part of the motor).

These windings are energized in a specific sequence to create a rotating magnetic field.

The rotor, which contains permanent magnets, is located inside (or outside in some designs) the stator.

It is free to rotate and is pulled toward the magnetic field generated by the stator.

In a sensor-based Brushless dc motor, Hall effect sensors detect the position of the rotor magnets.

This position information is sent to the Electronic Speed Controller (ESC) or driver circuit.

Based on the rotor's position, the controller switches the current through the appropriate stator windings.

This causes the magnetic field to rotate, continuously pulling the rotor along with it.

As long as power is supplied, the controller continues switching the currents in the correct order.

This creates a smooth and continuous rotation of the rotor.

The motor speed is controlled by adjusting the frequency of switching.

Torque is controlled by changing the amount of current supplied to the windings.

A Brushless dc motor works by synchronizing the rotor with a rotating magnetic field produced by the stator. Instead of relying on mechanical brushes, it uses an electronic controller to switch the current accurately and efficiently. This makes BLDC motors more reliable, efficient, and long-lasting than traditional brushed motors.

Thailand has emerged as a vital hub in the global brushless motor manufacturing industry, with a broad spectrum of companies producing high-performance motors for automotive, industrial, aerospace, and consumer electronics applications. This article provides a comprehensive guide to the top 20 Brushless dc motor manufacturers in Thailand, covering their company profiles, primary products, and unique advantages.

MinebeaMitsumi is a globally Brushless dc motor manufacturer in Thailand, primarily focused on precision machinery and motor solutions.

Brushless DC Motors (BLDC)

Stepping Motors

Cooling Fans

Cutting-edge R&D facilities

Robust global supply chain

High precision manufacturing standards

Delta Electronics, headquartered in Taiwan, is a leading Brushless dc motor manufacturer and has one of its major manufacturing facilities in Thailand, focusing on power and thermal management solutions.

BLDC Motors for HVAC

Industrial Cooling Fans

Energy-efficient Motion Solutions

Industry 4.0-enabled smart factories

ISO-certified facilities

Strong commitment to sustainability

Part of the Nidec Group, this Thai division is a leading Brushless dc motor manufacturer and specializes in motors for hard disk drives, electric vehicles, and home appliances.

BLDC Motors

Fan Motors

Miniature Precision Motors

World-class automation technology

Vertically integrated supply chain

Excellent quality assurance systems

A leading Japanese Brushless dc motor manufacturer with extensive Thai operations, Mabuchi Motor delivers reliable motor solutions globally.

Brushless DC Motors

Small Automotive Motors

Power Tool Motors

Focused on eco-friendly production

Advanced material engineering

Global OEM partnerships

Established in 1952, Siam Motors is one of the most diversified Brushless dc motor manufacturers in Thailand, with a significant presence in the motor sector.

BLDC Industrial Motors

Automotive Motors

Custom Electric Drives

Decades of market experience

Strategic joint ventures

Strong local distribution network

A division of Panasonic Corporation, this facility is a leading Brushless dc motor manufacturer and focuses on electric motors used in home appliances and industrial applications.

High-efficiency BLDC Motors

Ventilation Fan Motors

Washing Machine Motors

Advanced Japanese engineering

Environmentally compliant manufacturing

Consistent quality controls

Johnson Electric is a global Brushless dc motor manufacturer in motion subsystems, and its Thai plant is key to supplying motors across Asia.

BLDC Motors for Automotive and Medical

Custom Motion Solutions

Actuator Systems

Custom motor design capabilities

ISO/TS 16949 certifications

Extensive R&D investment

Kuroda Electric is a Japanese multinational operating a major distribution and assembly center in Thailand.

BLDC Motors

Motor Controllers

Electronic Drive Systems

Strong supply chain integration

Electronics and motion synergy

Precision engineering

Mitsubishi Electric's Thai division is a leading Brushless dc motor manufacturer and supplies automation systems and motor technology to numerous industries.

Servo and BLDC Motors

Industrial Automation Motors

HVAC BLDC Systems

Strong after-sales support

Leading-edge automation technologies

Local and international expertise

Part of the Hitachi Group, this company is a leading Brushless dc motor manufacturer and offers sophisticated solutions for industrial motors and systems.

Industrial BLDC Motors

HVAC Motors

Energy-saving Drives

High-performance engineering

Green manufacturing focus

Comprehensive maintenance services

Topband is a Chinese Brushless dc motor manufacturer with a rising presence in Thailand, offering smart motor and control solutions.

IoT-enabled BLDC Motors

Electric Vehicle Motors

Home Appliance Motors

Agile production capabilities

IoT and AI integration

Rapid prototyping

A local Thai Brushless dc motor manufacturer focusing on high-precision electric motors for the export market.

Custom BLDC Motors

Precision Gear Motors

Micro BLDC Systems

In-house design and tooling

Cost-effective production

Strong export capacity

LSP is a leading Brushless dc motor manufacturer and known for industrial electric motor production serving sectors like HVAC, manufacturing, and logistics.

Three-phase BLDC Motors

HVAC and Compressor Motors

Explosion-proof Motors

Localized engineering solutions

Fast lead times

High endurance ratings

A Thai-owned Brushless dc motor manufacturer specializing in medium- to large-sized electric and brushless motors.

Industrial BLDC Units

Power Transmission Systems

Custom Motor Assemblies

Tailored motor designs

Strong customer support

Competitive pricing

A German Brushless dc motor manufacturer operating in Thailand, EBM-Papst is famous for energy-efficient fans and motors.

Compact BLDC Motors

High-performance Fan Motors

EC (Electronically Commutated) Motors

Unmatched energy efficiency

German engineering standards

Long lifespan and low noise

A joint venture between Toshiba and Mitsubishi, TMEIC is a leading Brushless dc motor manufacturer and delivers advanced drive and motor systems.

High-torque BLDC Motors

Industrial Automation Motors

High-capacity Inverter Drives

Smart grid-ready systems

Global quality control processes

Industrial AI support

Fuji Electric is a Brushless dc motor manufacturer and manufactures a wide range of electric motors and control systems from its Thai factory.

BLDC Motors for Pumps and Compressors

Servo Drives

Industrial Control Panels

Advanced motor analytics

Superior system integration

Japanese quality assurance

With global origins, Oriental Motor’s Thai operations is a leading Brushless dc motor manufacturer and offer motors for automation and robotics.

Compact BLDC Motors

Precision Servo Motors

Linear Actuators

Quick delivery systems

Compact, modular design

Focus on mechatronics

Jkongmotor is a global Brushless dc motor manufacturer in electrification and automation technologies with a large presence in Thailand.

Industrial-grade BLDC Motors

Smart Motion Control Systems

Robotics Integration Motors

Cutting-edge automation

Low energy consumption

Industrial AI capabilities

A well-established china Brushless dc motor manufacturer with Thai facilities that serve Southeast Asia’s motor needs.

BLDC Gear Motors

Modular Drive Systems

Energy-saving Motor Solutions

Modular design flexibility

High torque, low weight

Efficient logistics support

Brushless dc motors (BLDC Motors) offer several advantages over traditional brushed motors, making them ideal for a wide range of applications—from consumer electronics and medical devices to electric vehicles and industrial machinery.

BLDC motors are more energy-efficient due to the absence of friction from brushes.

They convert more electrical energy into mechanical power with minimal energy loss.

Since there are no brushes to wear out, Brushless dc motors have a significantly longer operational life.

They are ideal for applications requiring long-term reliability.

The lack of brushes means no regular replacements or servicing is needed.

This reduces downtime and maintenance costs, especially in industrial environments.

BLDC motors operate with minimal noise since there's no brush-commutator contact.

This makes them perfect for home appliances, medical equipment, and office devices.

BLDC motors offer precise speed and torque control using electronic controllers.

They maintain consistent performance under varying loads.

They are smaller and lighter for the same power output compared to brushed motors.

Ideal for portable devices, drones, and electric vehicles.

BLDC motors deliver high torque even at low speeds, which enhances performance.

This makes them efficient for applications like robotics and e-bikes.

Without brushes, there’s no electrical sparking, making Brushless dc motors safer in hazardous or flammable environments.

BLDC motors can operate at very high speeds, thanks to electronic control and the absence of mechanical limitations.

With stationary windings, heat is easier to dissipate from the stator, allowing for better thermal management.

Brushless dc motors offer superior performance, durability, and efficiency compared to traditional motors. Their many advantages make them the preferred choice in modern, high-tech applications where precision, reliability, and efficiency are essential.

Brushless DC Motors (BLDC Motors) are widely used across multiple industries due to their high efficiency, compact size, reliability, and precision control. Below are the key application areas where BLDC motors play a vital role:

Electric Vehicles (EVs): BLDC motors are extensively used in electric cars, e-bikes, and scooters due to their high torque, efficiency, and low maintenance.

Power Steering Systems: For precise control and smoother operation.

Fuel Pumps and HVAC Systems: For reliable and efficient vehicle systems.

Cooling Fans: In computers, gaming consoles, and home appliances.

DVD/CD Drives: For quiet and smooth disc rotation.

Printers and Scanners: Used in actuators and moving mechanisms for precise motion.

Washing Machines: Brushless dc motors allow quieter operation, energy savings, and high-speed control.

Air Conditioners and Refrigerators: For variable speed compressor control.

Vacuum Cleaners: Compact, lightweight design enables powerful suction and better mobility.

CNC Machines: For accurate and responsive movement in machining and cutting tools.

Robotics: BLDC motors are used in robotic arms, actuators, and servo systems for high precision control.

Conveyor Systems: Efficient and durable for 24/7 industrial use.

Ventilators and Pumps: For consistent, quiet, and reliable performance.

Surgical Tools: High-speed and sterilizable BLDC motors ensure safety and precision.

Mobility Aids: Such as motorized wheelchairs and patient lifts.

Drones and UAVs: Lightweight and high-power BLDC motors provide smooth, high-speed operation and quick response.

Missile Guidance Systems and Actuators: Where high reliability and accuracy are mission-critical.

Drills, Screwdrivers, and Saws: Brushless dc motors offer longer battery life, higher power output, and reduced heat generation.

Cordless Tools: Ideal due to their lightweight and efficient power delivery.

Variable Speed Fans and Compressors: Energy-efficient operation in heating and cooling systems.

Air Handling Units: For smooth and controlled air movement in buildings and industrial setups.

Wind Turbines: Used in pitch control and yaw systems.

Solar Panel Tracking Systems: BLDC motors move panels to optimize solar gain throughout the day.

Automated Equipment: In irrigation systems, feeding units, and harvesting machines.

Drones: Used for crop spraying, mapping, and monitoring.

Thanks to their efficiency, precision, durability, and adaptability, Brushless dc motors are indispensable in modern technologies across nearly every sector. Whether powering electric vehicles, enabling precise surgical tools, or automating factory floors, BLDC motors deliver reliable performance in even the most demanding applications.

Thailand’s brushless motor manufacturing landscape is both rich and diverse. From large multinational corporations to agile local innovators, the country offers world-class capabilities in BLDC motor production, serving industries from automotive to aerospace. These manufacturers not only support Thailand's robust industrial base but also contribute significantly to the global supply chain.

View More(Total0)Comment Lists