Planetary gear reducers are compact components that strive to maximize the transmission of torque in various applications. The mechanisms ensure the transmission of high torque levels while simultaneously decreasing the required number of motor revolutions for a set level of power.

Generally, planetary gears are used as speed reducers. They are used to slow down motors and increase the torque. Torque is the working power of the machine.

A planetary gearhead takes a high-speed, low-torque input, say from an electric motor, then increases torque and reduces speed at the output by the gearhead ratio. This lets motors run at higher, more-efficient rpms in equipment that operates at low speeds.

It also enables high torque transmission in a small construction space thanks to the use of multiple parallel tooth combinations with several orbiting wheels. As the torque is distributed over several gear wheels, the tooth forces are smaller than in other types of gear.

A gear reducer is a mechanical transmission device that connects a motor to a driven load. It is also known as a gearbox. It allows you to modify the torque and speed between a motor and a load. Reduction gear assemblies are made up of series of gears.

High efficiency due to low rolling power. Almost unlimited transmission ratio options due to combination of several planet stages. Suitable as planetary switching gear due to fixing this or that part of the gearbox. Possibility of use as overriding gearbox.

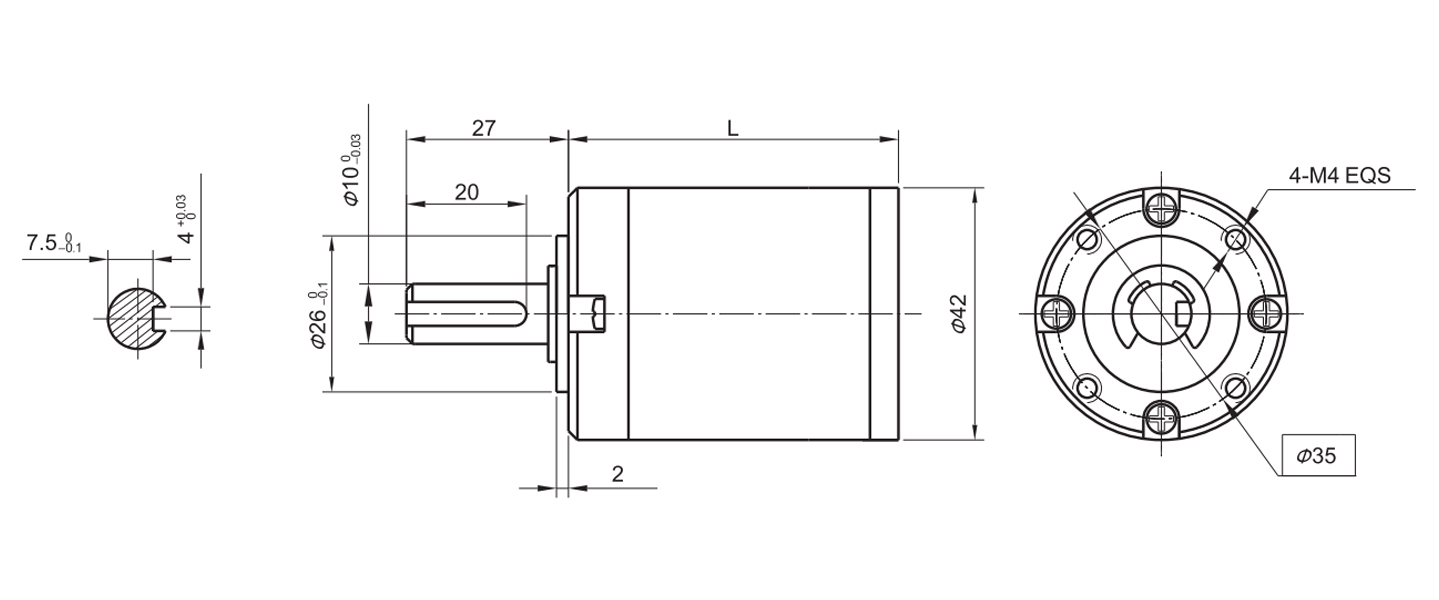

| 42JXE100K | |

| Ring material | Metal / Powder metal |

| Bearing at output | Ball bearings |

| Max. Radial (12mm from flange) | 200N |

| Max. shaft axial load | 100N |

| Radial play of shaft (near to flange) | ≤0.06mm |

| Axial play of shaft | ≤0.3mm |

| Backlash at no-load | ≤2.5° |

| Shaft press fit force, max | 150N |

| Gearbox Specifications: | ||||||

| Reduction ratio | Exact reduction ratio | Rated tolerance torque | Max momentary tolerance torque | Efficiency | L (mm) | Weight (g) |

| 1/3.7 1/5.2 | 1/3.71 1/5.18 | 1.0 N.m Max | 3.0 N.m | 90% | 31.5±0.5 | 244 |

| 1/14 1/19 1/27 | 1/13.73 1/19.20 1/26.85 | 4.0 N.m Max | 12 N.m | 81% | 42.1±0.5 | 314 |

| 1/51 1/71 1/100 1/139 | 1/50.89 1/71.16 1/99.51 1/139.14 | 8.0 N.m Max | 25 N.m | 73% | 52.5±0.5 | 433 |

| 1/181 1/218 1/253 1/305 1/354 1/426 1/495 1/596 | 1/180.96 1/218.12 1/253.03 1/304.99 1/353.80 1/426.46 1/494.71 1/596.31 | 10 N.m Max | 30 N.m | 66% | 62.9±0.5 | 519 |

| Input & output same rotation direction; Motor Max. input speed: <8000rpm; Operating temperature range: -15℃ ~ +80℃ | ||||||

| BLDC Motor Shaft Pinion Specifications | ||

| Module | 0.6 | |

| No. of teeth | 11 | 17 |

| Pressure angle | 20° | |

| Hole diameter | Φ3.16 Φ3.98 Φ4.48 | |

| Reduction ratio | 1/5.18 1/19 1/27 1/71 1/100 1/139 1/253 1/305 1/354 1/426 1/495 1/596 | 1/3.71 1/14 1/51 1/181 1/218 |

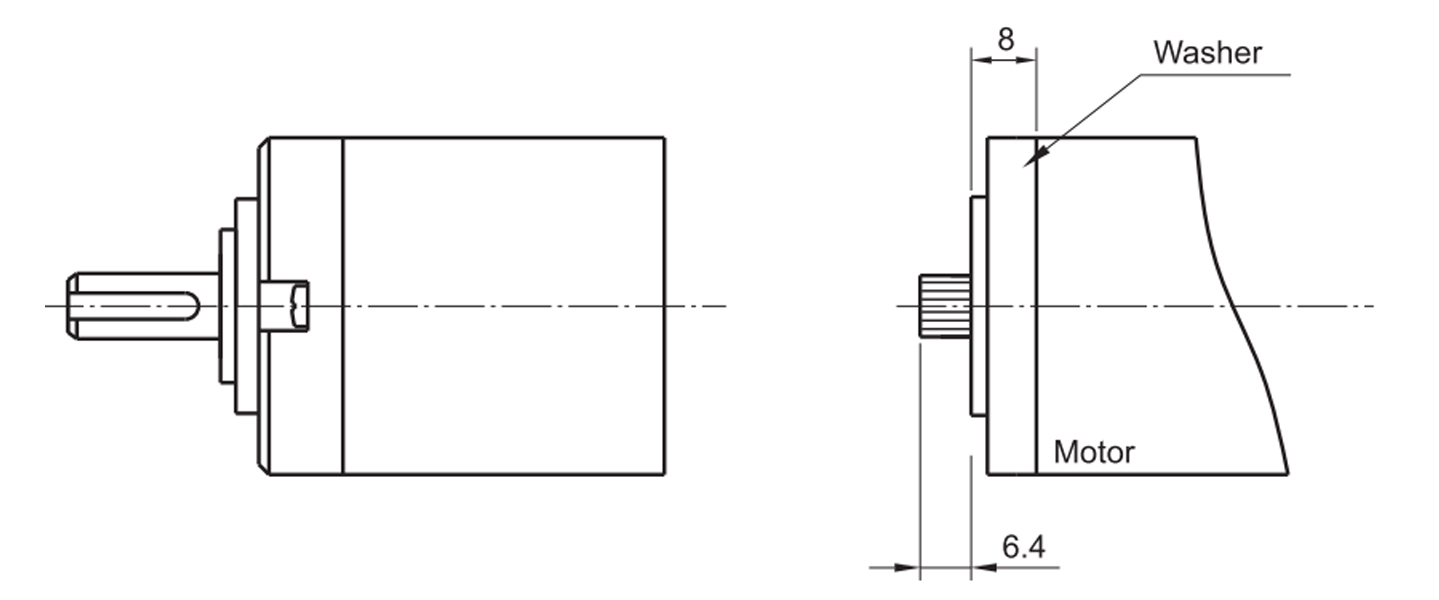

Product Type: JK42BL Round Planetary Gearbox Reducer for Geared BLDC Motor

Size:42x42mm

Place of Origin:china

Minimum order quantity:10pcs

Material Science:stator, rotor, stainless steel shaft, copper wire, magnetic steel...

Feature summary: Low Inertia,Quick Feedback; High Torque,High Efficiency; Small Vibration,Low Noise

Packing:The sample is packed in carton,the batch with plastic pallet

Delivery time:Standard product: 7-10days

Customized product: 25-30days

Transaction mode:EXW, FOB, FCA, CIF, FAS, CFR, CPT, CIP, DAF, DEQ, DDU, DDP...

APPLICATION:Medical equipment: medical pumps, stirring instruments, peristaltic pumps, biopharmaceutical equipment. Industrial equipment: winding machines, printing machines, robots, grinding, cutting, drilling, automatic conveying systems, automatic positioning systems, level control systems, electric actuators, electric valves, vending machines.

If this motor do not match with your request. Please feel free to contact with us,We can make customized shaft / winding / mounting flange / cable / connector / Encoder / Brake / Gearbox and others. We will works side-by-side with you and your team to design a motor that will fit the precise needs of your application. All Engineering and Support is done in-house.

Brushless DC Motor Model: JK42BL-Round BLDC Motor / JK42BLS Square DC Brushless Motor